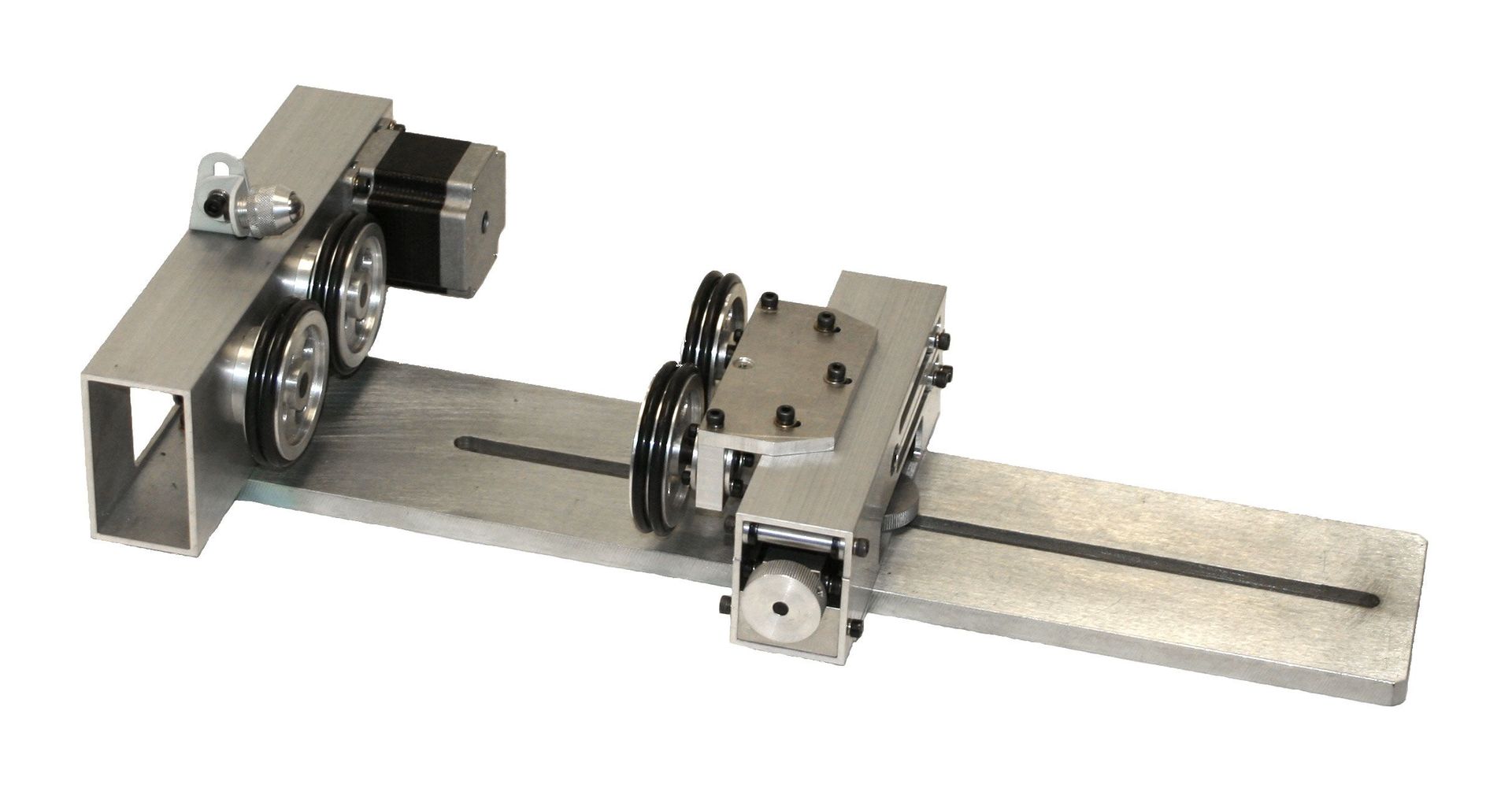

- Versatile: Handle a wide range of round objects.

- Easy Setup: Place the object on the rollers, align it, and you’re ready to engrave.

- Fast Workflow: Perfect for production runs of cups or bottles.

- Consistent Results: The smooth rolling motion gives even engraving across the surface.

Roller vs. Chuck: Laser Showdown!

When it comes to cylindrical engraving, the type of rotary you use can make all the difference. Roller and chuck rotaries each have their strengths, and the right choice depends on what you’re engraving. Let’s break down the differences so you know which one to use for your next project.

Roller Rotaries

Roller rotaries use a set of wheels to spin your object during engraving. They’re quick to set up and great for everyday jobs like tumblers, bottles, and glasses.

Advantages of Roller Rotaries

Best For: Standard tumblers, water bottles, and objects without handles.

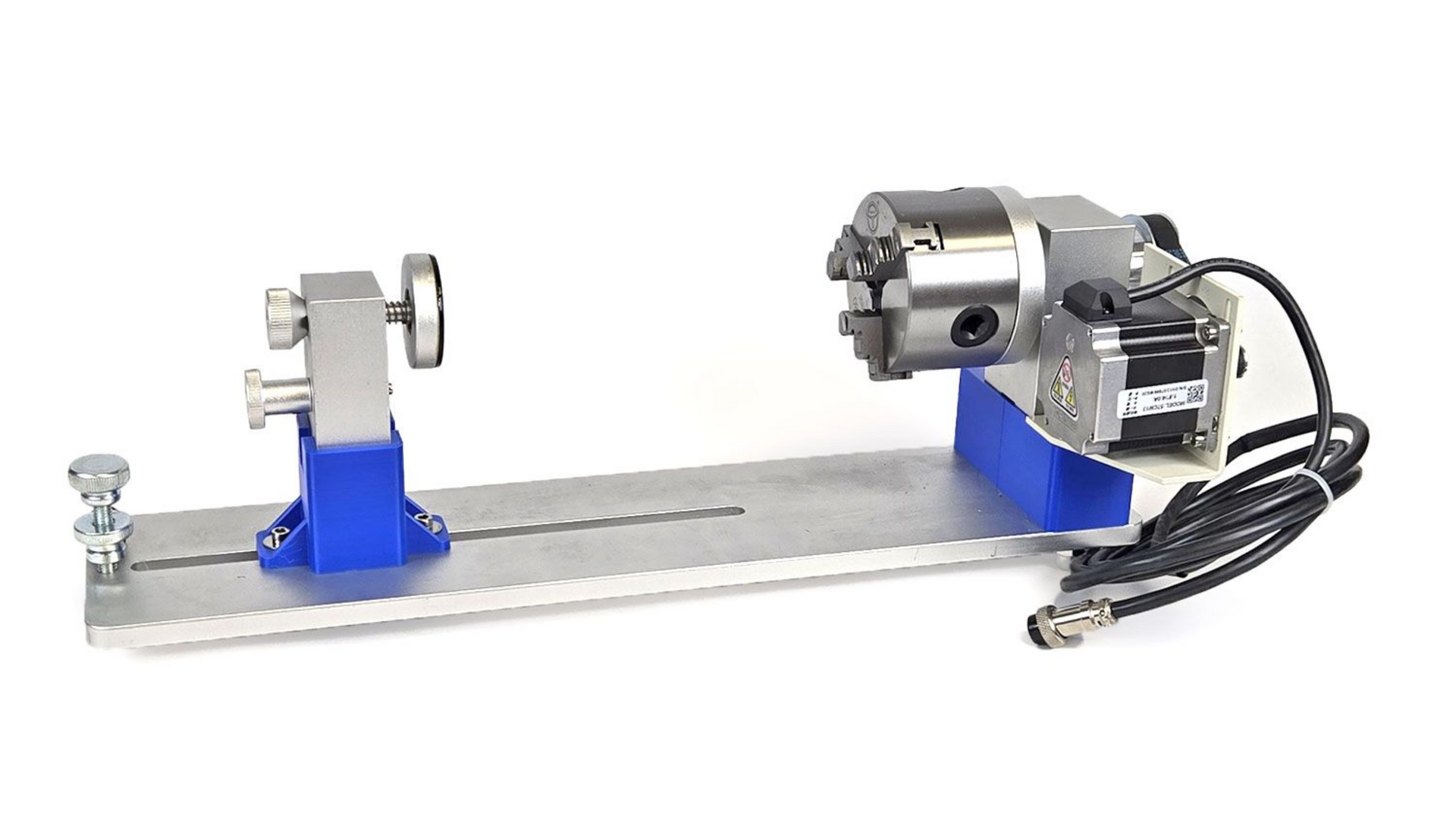

Chuck Rotaries

Chuck rotaries grip your object with a clamp, much like a lathe. This makes them ideal for items that can’t sit securely on rollers, or when you need precise alignment.

Advantages of Chuck Rotaries

Best For: Mugs with handles, irregular shapes, and projects that need exact placement.

Which One Should You Choose?

- Go with a roller if you’re engraving a lot of tumblers, bottles, or simple cylinders.

- Pick a chuck if you’re working with mugs, need exact alignment, or want to engrave irregular shapes.

Some laser owners keep both on hand — using rollers for speed and chucks for tricky jobs.

Final Thoughts

Both

roller and

chuck rotaries expand what’s possible with your

CO2 laser. The best choice depends on your projects, but either one will take your engraving beyond flat surfaces. If you’re just starting out, try a roller for everyday use, then add a chuck when you’re ready for more complex work. 🐰