- 2” masking tape (paper tape works best)

- Scissors

- Pen or marker (dark color)

- Phillips screwdriver

- Mirror adjustment tool or fingers (depending on mounts)

- Paper towel

- Denatured alcohol (optional cleaning)

Laser Beam Alignment for Flying Optics Machines

A practical maintenance guide for consistent cutting and engraving

Laser alignment is one of the most important maintenance tasks on a flying optics machine. Even a small shift in the beam path can cause weak cuts, angled edges, power loss, or clipping inside the nozzle.

The good news is alignment is mechanical and repeatable. Once you understand the process, it becomes a straightforward maintenance routine.

This guide walks through a clean step-by-step alignment using the machine’s built-in pulse/test fire function and simple tools. No special equipment required.

Tools & Materials

Before You Begin

Alignment assumes:

- Laser tube fires normally

- Coolant is flowing

- Mirrors are clean

- Nothing inside the machine is loose

Only use short pulse bursts.

Keep all covers closed during firing.

Alignment must be done in order.

Mirrors are named:

- Mirror 1 — closest to the tube

- Mirror 2 — gantry mirror

- Mirror 3 — head mirror above the nozzle

Phase 1 — Tube → Mirror 1 Check

Before adjusting anything, confirm the beam is entering mirror 1.

Open the rear compartment and visually inspect:

- Tube points directly at mirror 1

- No obstructions

- Path looks centered

If the beam misses mirror 1 entirely, correct tube positioning first. Alignment cannot begin until the beam hits the first mirror.

Phase 2 — Mirror 1 → Mirror 2 Alignment

This aligns the beam along the Y-axis travel.

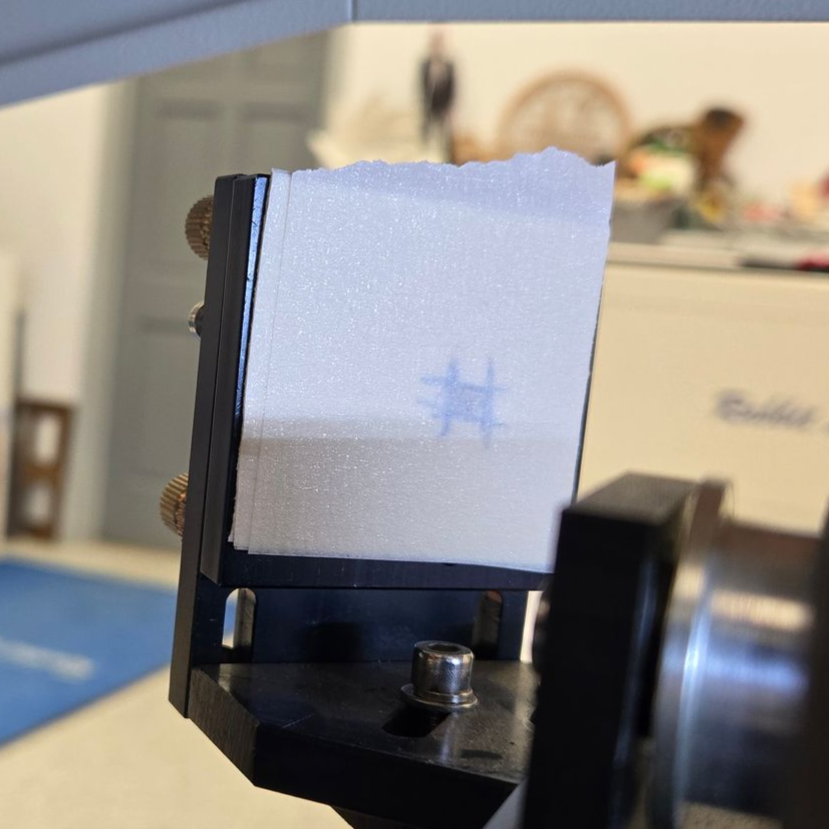

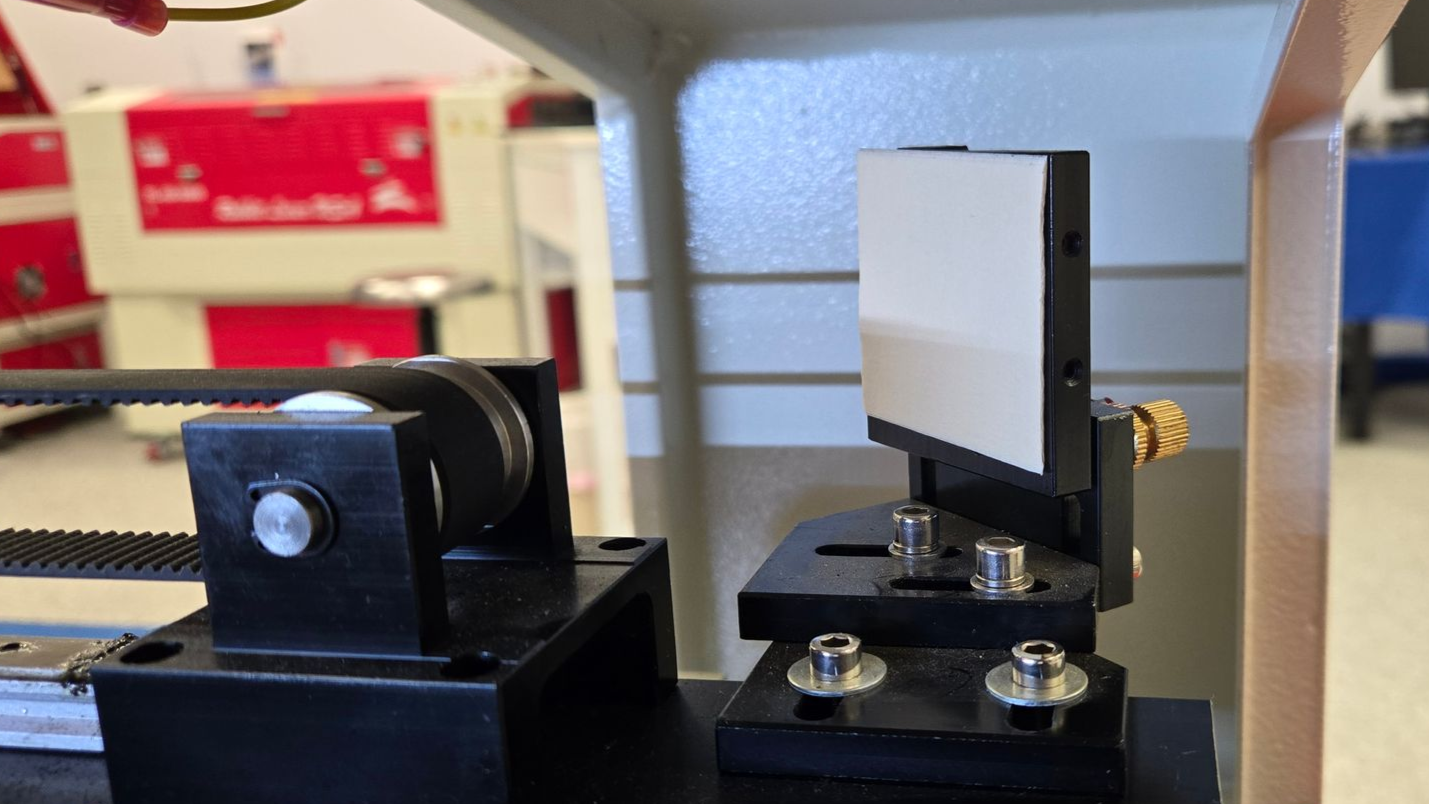

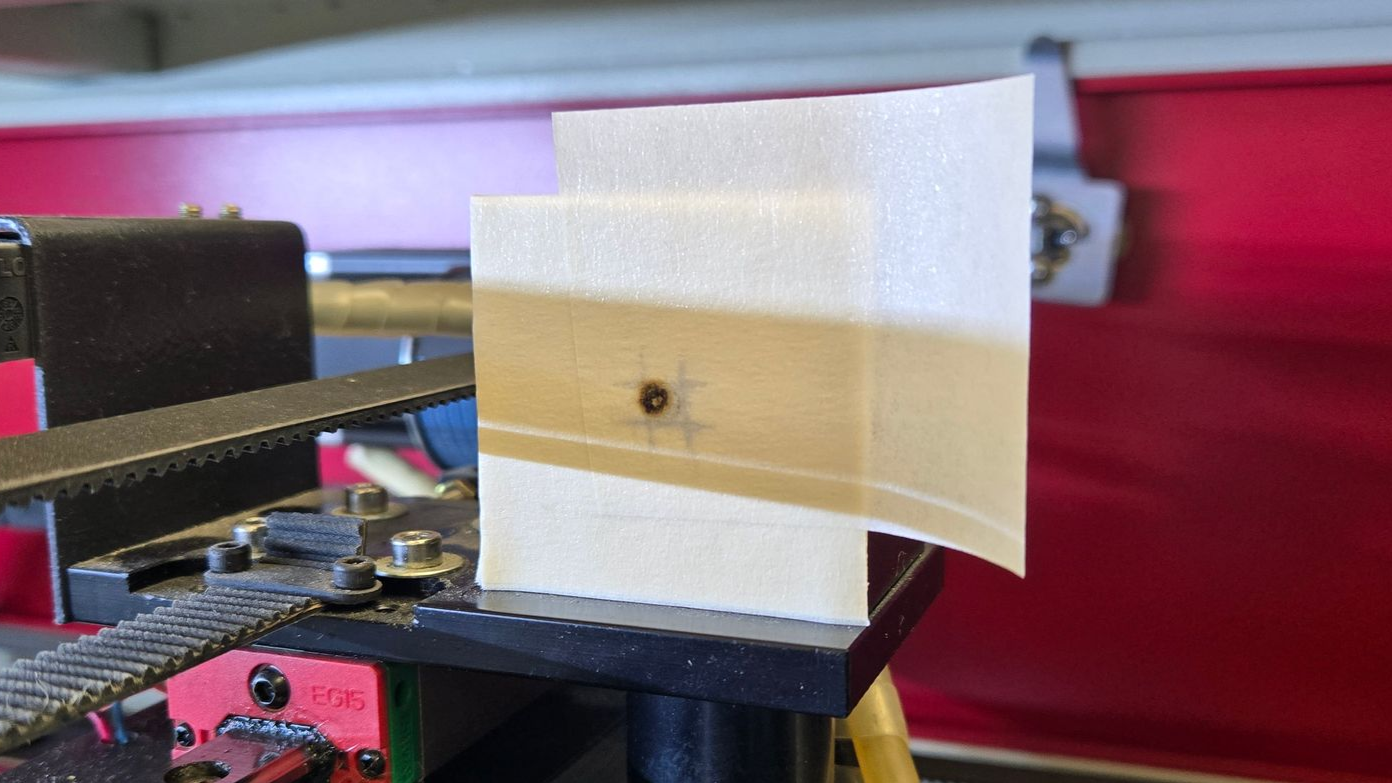

Step 1 — Create a Target

Layer masking tape into a thick pad (10–15 layers).

Place the target on the bracket of mirror 2.

The tape must not touch the mirror surface.

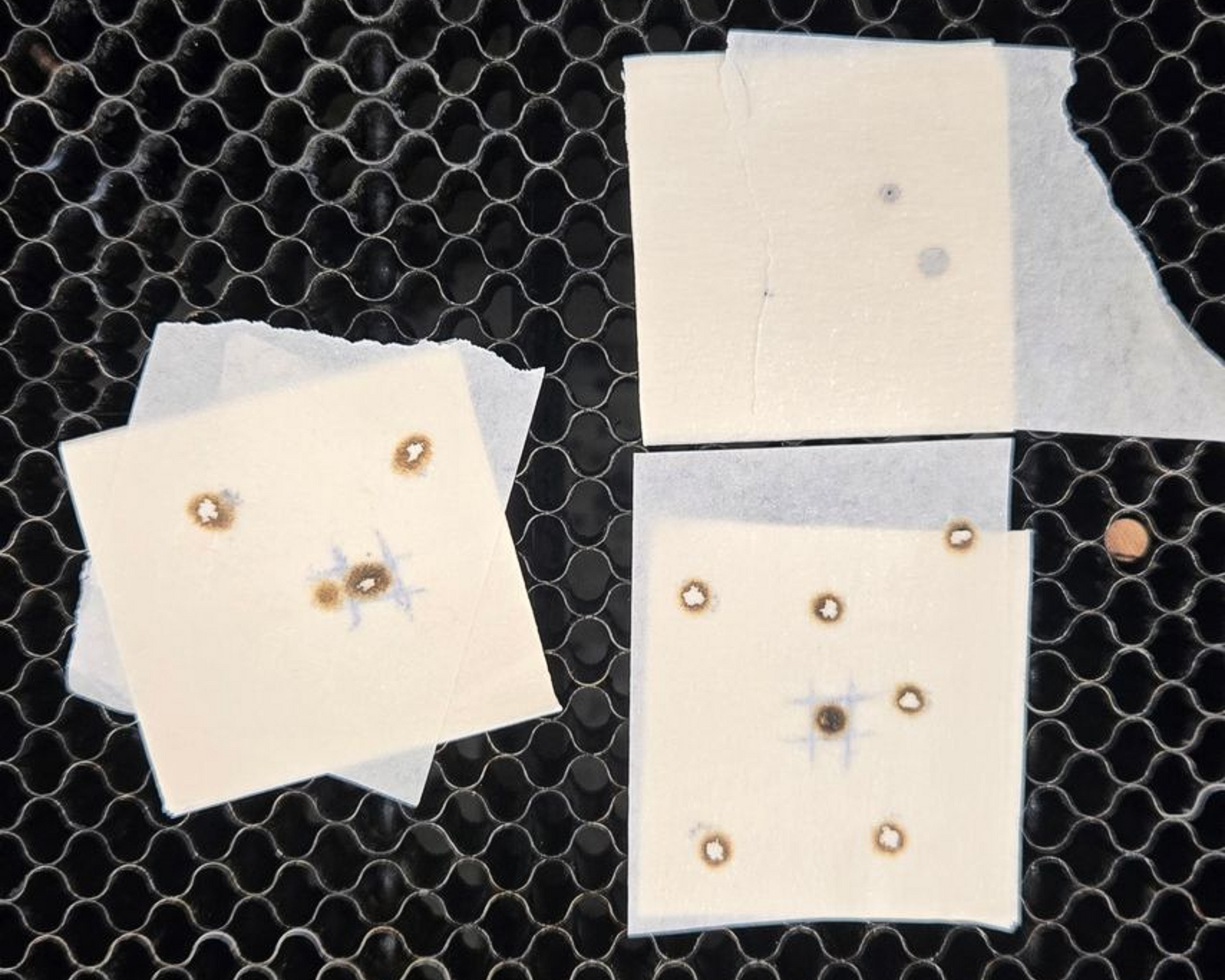

Step 2 — Rear Position Test

Move the gantry to the rear of the machine.

Close the lid and fire a short pulse.

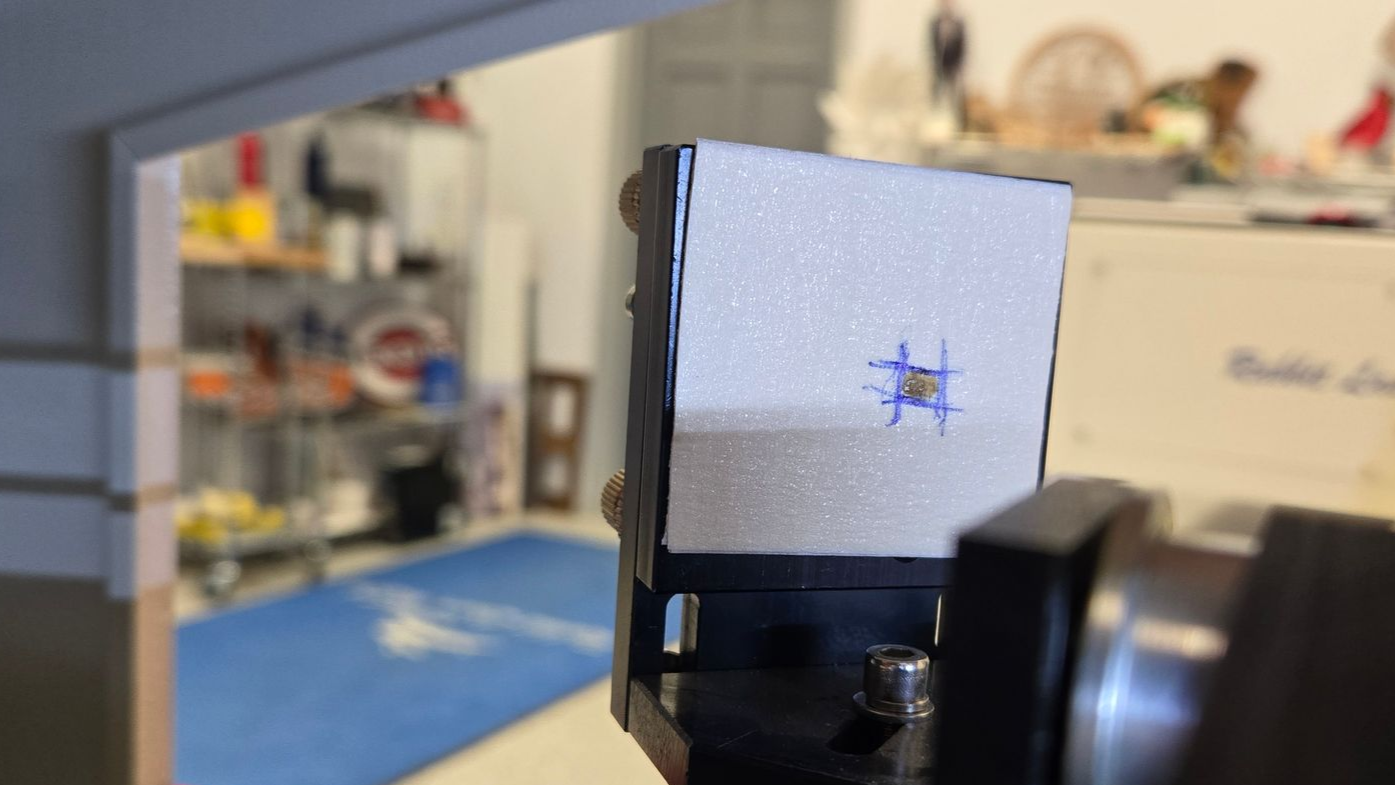

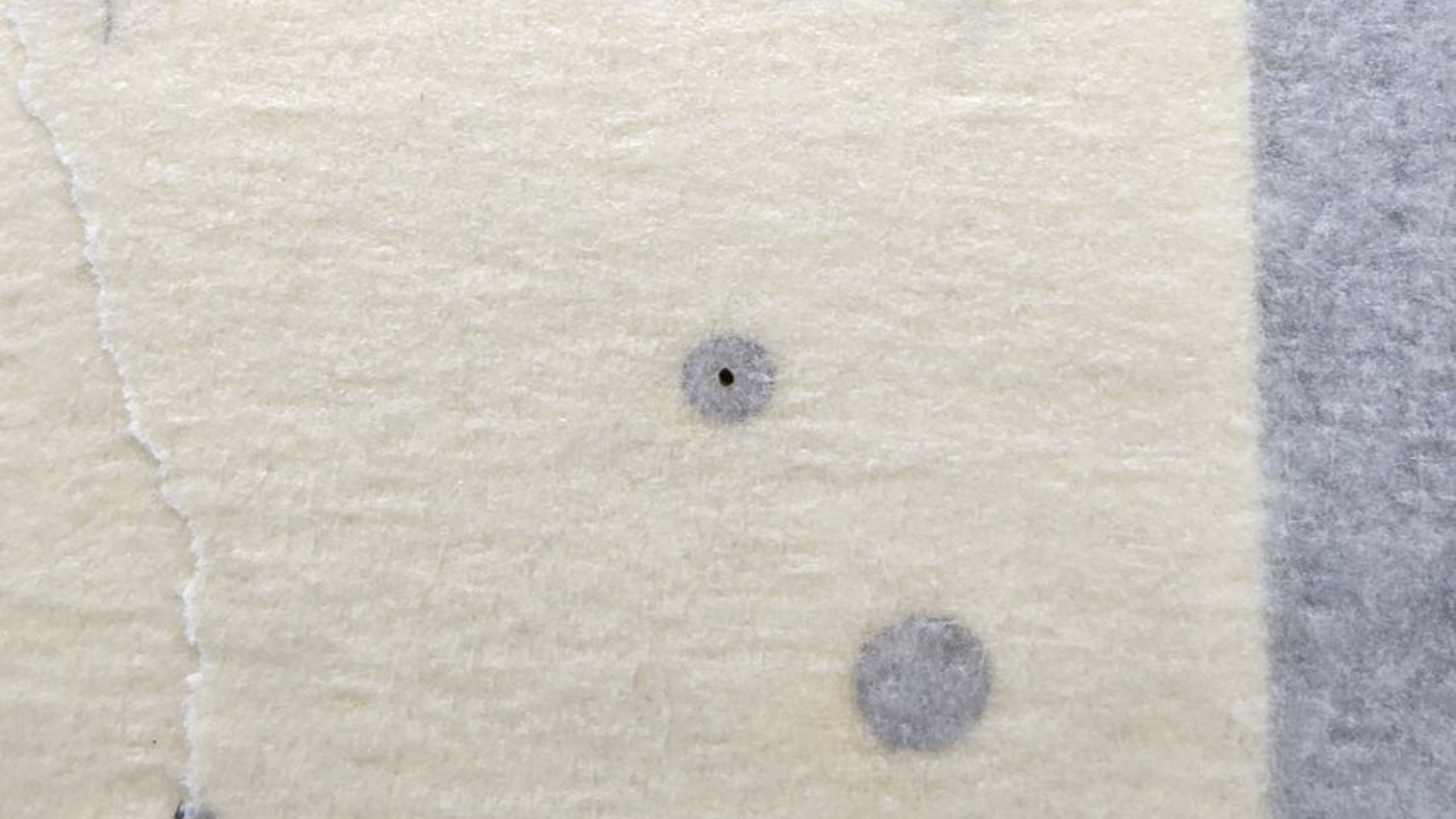

You should see a dark oval burn.

Mark the edges of the burn with a pen.

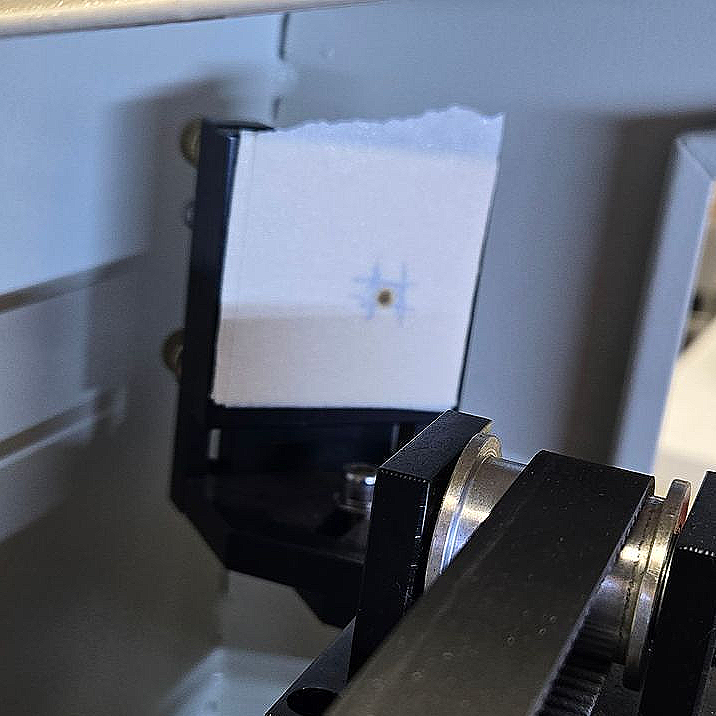

Step 3 — Front Position Test

Move the gantry to the front.

Cover the target with fresh tape.

Pulse again.

Compare the new burn to the original.

Step 4 — Adjust Mirror 1

If the two burns do not overlap:

Adjust mirror 1 screws slightly.

Use very small turns.

Even 1/16 turn can be enough.

Repeat rear → front testing until the burns land in the same spot.

Goal: identical burn location regardless of gantry position.

When the marks overlap, mirror 1 is aligned.

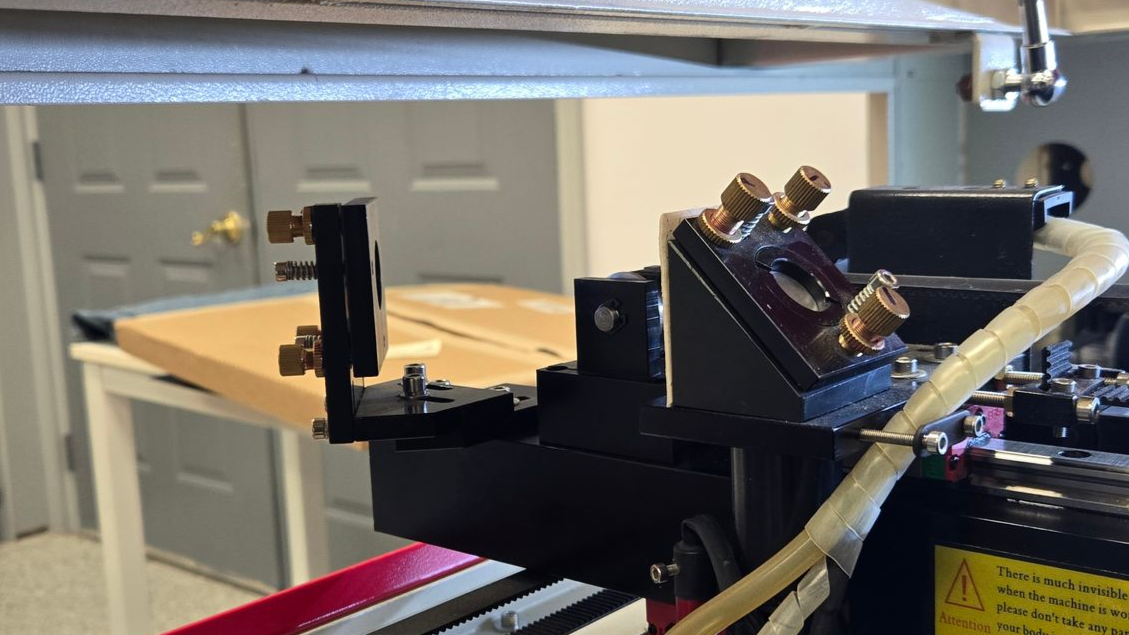

Phase 3 — Mirror 2 → Mirror 3 Alignment

This aligns the beam along the X-axis.

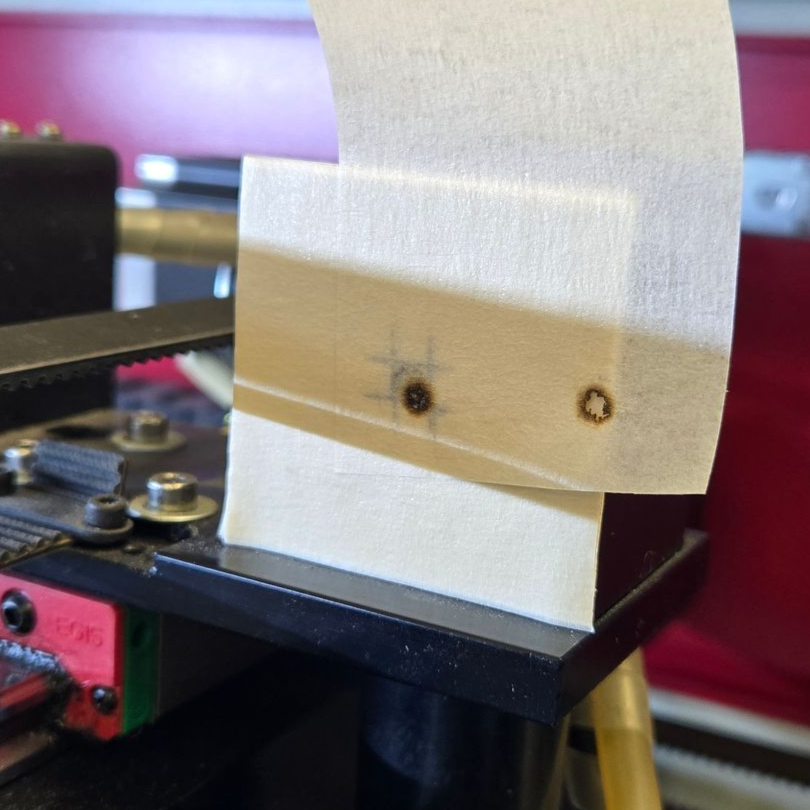

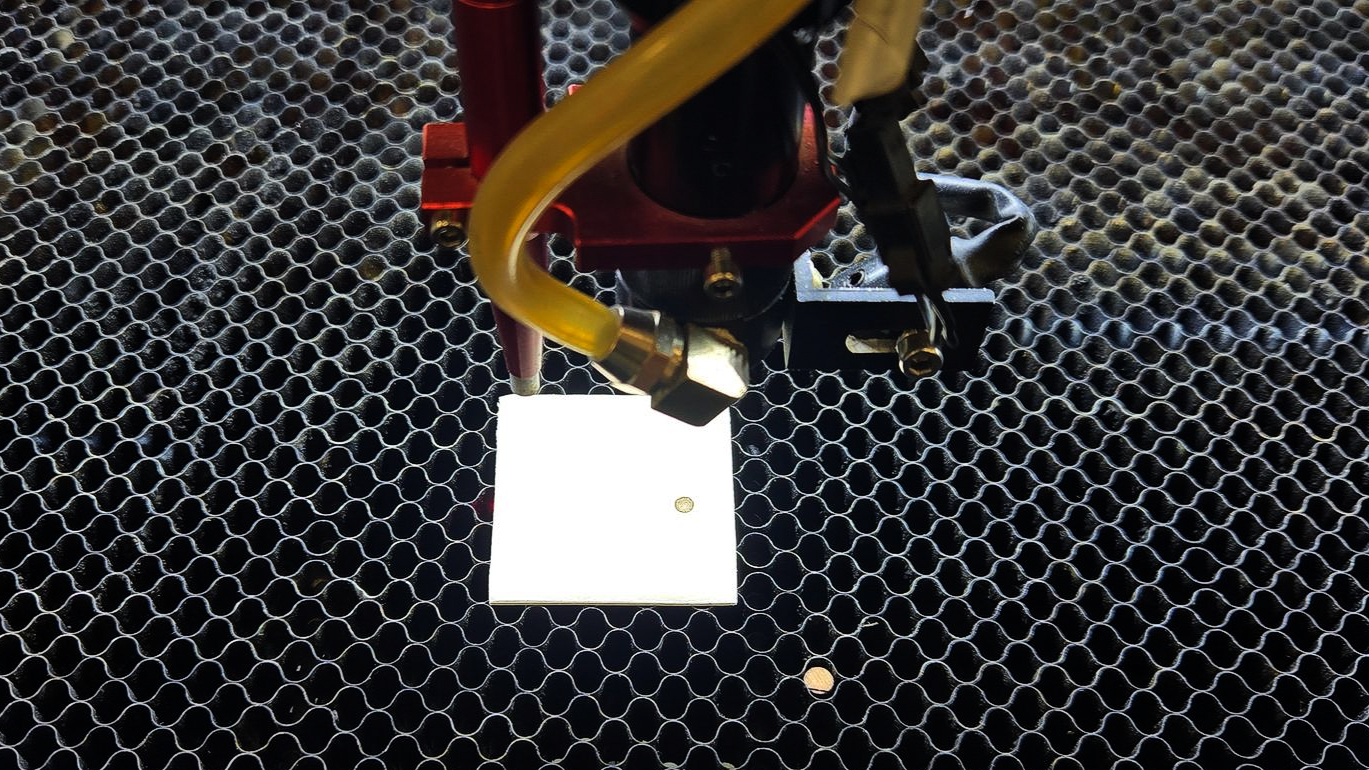

Step 1 — Move Target

Place a layered tape target on mirror 3.

Step 2 — Left Position Test

Move the head fully left.

Pulse once.

Mark the burn.

Step 3 — Right Position Test

Move the head fully right.

Cover with fresh tape and pulse again.

Step 4 — Adjust Mirror 2

Use mirror 2 screws.

Repeat left/right testing until the burns overlap.

When both positions match, mirror 2 is aligned.

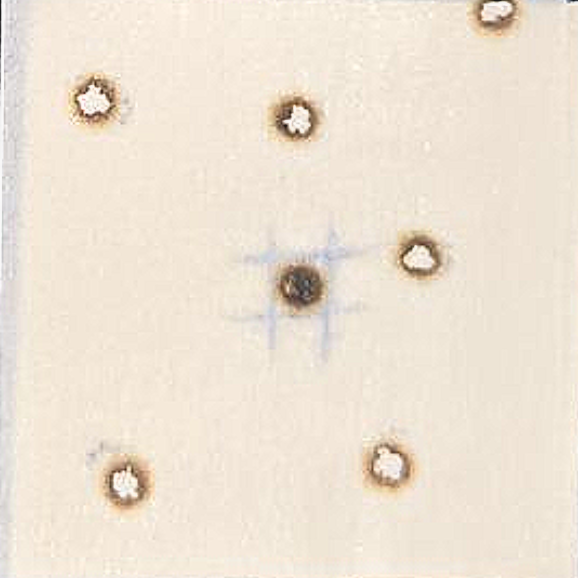

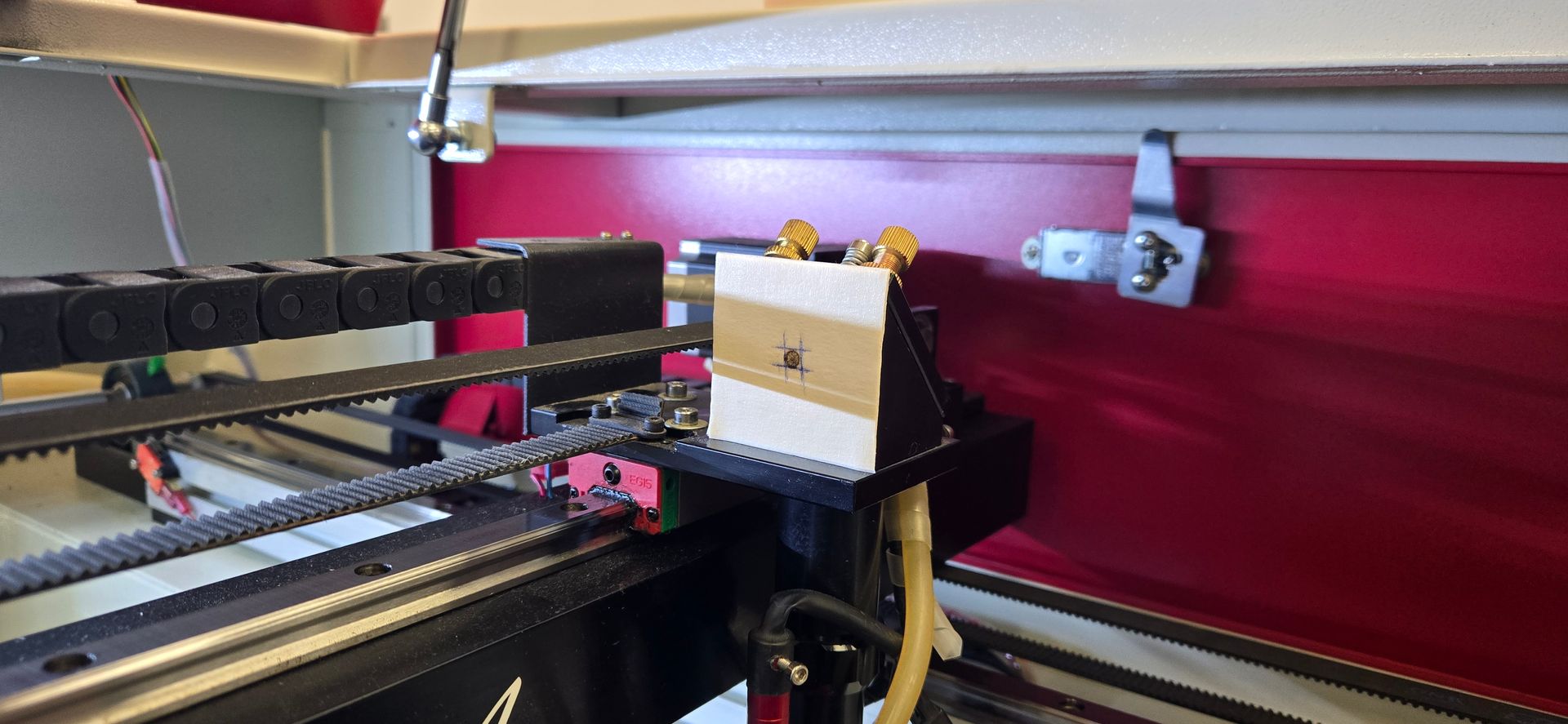

Phase 4 — Centering the Beam Into the Head

Place a 3-layer tape target over the entry hole of the head.

Trace the circular opening with a pen.

Move the head to the center of the table.

Pulse once.

The burn should be:

- centered in the circle

- slightly above center (normal)

If off-center:

Make fine adjustments to mirror 2 and mirror 3.

Repeat until centered and consistent.

Phase 5 — Final Spot Check at the Table

Place tape flat on the work bed.

Lower the table slightly out of focus.

Pulse once.

You should see:

- a clean round spot

- smooth edges

- no crescent or clipping shape

If the spot looks distorted, the beam may be hitting the nozzle and requires minor adjustment.

Alignment Complete

Alignment is finished when:

- rear/front burns match

- left/right burns match

- head entry is centered

- final table spot is round

At this point the beam path is straight and consistent.

Quick Troubleshooting Guide

Burn shifts front to rear

→ Adjust mirror 1

Burn shifts left to right

→ Adjust mirror 2

Spot clips inside nozzle

→ Beam not centered into head

Weak cutting power

→ Alignment issue or dirty mirrors