Customer Stories of Laser Professionals, Small Businesses & Hobbyists

Sometimes we have adventures with our customers that we just NEED to share. Come back for more laser success stories...

When deliveries become adventures

When we started delivering laser machines, we figured it would be straightforward: take the machine inside, hook up the parts, power it on and show the customer how to use it. In practice, every delivery is its own adventure. Each shop has a unique layout, each customer has different needs and everyone has their own expectations. We keep a sense of humor to get through the tricky parts, then focus on training once the machine is in place.

On a good day, we roll the laser out of the trailer, down a ramp and through a double door into a room that already has a vent and outlet. That ideal setup happens about once in fifty deliveries.

Memorable installation moments

- We once lifted a machine four feet, slid it through a window and across a workbench. Someday they’ll have fun getting it back out.

- At another shop the laser didn’t fit through the door. While I went to grab a tape measure, the owner pulled off the door frame. “We needed a bigger door anyway,” he laughed.

- A downtown office had a tiny entrance. We rode a freight elevator up, wheeled through someone else’s woodshop, down a hallway and through a smaller door. Next time we’ll plan the route better.

- Without a forklift, a customer used two 2×10 boards as a ramp from our truck bed up to the dock. Wobble, wobble—need I say more?

- It took six people to lift an RL‑60‑9060 through a doorway five feet off the ground with no ramp or steps. Probably not the best place for a door.

- Sometimes the hardest part is just getting to the site. One delivery took us up a narrow mountain road and through the woods. The view from the back porch made the trip worth it.

- Once, two retirees and I carried a machine down a 32‑inch‑wide staircase. We got the laser down without breaking a hip.

- And yes, we’ve delivered in snowstorms, rain and even after a spin‑out on I‑70 in January. The truck earned some “character” marks that day, and I learned the value of HEET fuel additive.

Cameron and Jaimeleigh (with much help from Tyson) run WUDN (pronounced wooden, of course) Using three of Ray’s excellent lasers, WUDN delivers a full line of handcrafted real wood products including phone cases, battery charging cases, sunglasses, and home, office & bar accessories. Most WUDN products are customizable with your name, monogram, logo or image. Learn more at: www.shopwudn.com.

Kevin and Debbie have a self-storage company and decided to use their extra office space to run an embroidery shop. They just added the laser machine and are looking forward to making awards, lasered denim, and other novelties.

Training at the Space Mann's facility.

Tammy proudly holds up her name tags. Tammy was one of my first customers.. I was in town and decided to stop by for a visit. I ended up doing a re-alignment on the laser beam, replaced the mirrors, and gave her some more training on the software. A great customer. You can visit her store (Party Town) in Woonsocket, RI.

Dale and his assistant show off the stuff they made while I did the delivery, setup, and training. The primary need for his company was to engrave onto stainless steel with "Thermark". After verifying the Thermark works great, Dale started grabbing anything else he could engrave on. You can see that he pulled a tile off of the floor, cut a piece of wood off a skid, and even took the mirror out of the men's restroom. This man was excited and very pleased with the results.

Mike is my kind of guy. He uses "drops" (scrap material) from his daytime employer's production processes. The wood is engraved and cut to make items for his business.

Josh and his wife own the company RPI, in which they now use the laser for making parts and novelties.

Jeff (Jay) makes "Journey Signs" for the major moments in a person's life and how far the crossroads are from your home.

Mark and his team operate an airbrush company in Panama Beach, FL. His hands might look empty, but he is holding up a plastic template for airbrushing T-shirts.

This lasered template took just over a minute to cut... The previous method was to use an exacto knife and took over 30 minutes for the artist to manually cut.

We never know where we will have to put the laser machine. This one was a surprise, but we did borrow a forklift from a friendly business neighbor.

Vince Biondo came to get his RL-60-9060 (60 watts, 36"x24" work area). We gave him lots of training here, proved it could do the work he needed, and loaded it into his truck for him. He got here around 1PM.. (20 minutes after I got back from an all-night (17Hours) drive from Florida)...Vince was super interested in learning about the machine as much as possible... His departure was also extra late, but he wanted to get all the training I could give.. (before I ran out of energy and just had to go get some sleep.) Vince runs a custom machine shop and is adding this to his army of machines to serve the customers.

Tom Cleland purchased the RL-80-1290 (80 watts, 48x36 inches). He is using his machine to make RC airplanes from foam-board. Tom also produces high-end acrylic swirl blanks for pen kits. He then engraves the acrylic pens however the customer asks.

Steve Hess and his wife produce custom pens and pencil kits. These kits are extra special. The wooden section of the pen is actually a puzzle of many kinds of woods. Steve has plans to make "Entarsia" style kits for inlaying on the pen body.

Sean and Mike just started a company to do custom engraving.. and more edge-lit glow signs. These guys are "Super Stoked" about the endless opportunities.

Heritage Signs uses the 120 Watt laser to cut acrylic contours and specialty engraving.

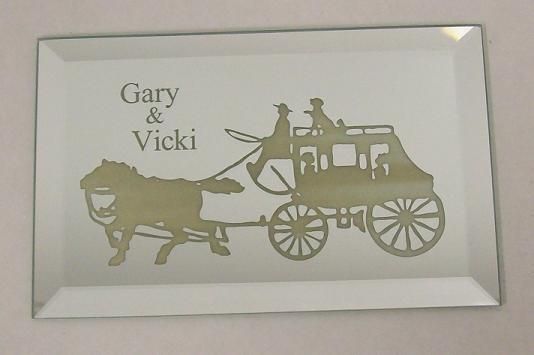

Gary uses his RL-40-6040 (40 Watts) to engrave pens and pencils. Gary has perfected a way to encase carbon fiber into epoxy resin .. no bubbles.. The resulting pens look great. Also see the mirror and other pens he makes.

Mike Daniels is supposed to be retired, but he just can't quit. He now spends his time making custom fishing poles. He turns the handles in his lathe. He hand wraps the loops and threads.. Then he engraves your name and favorite fish into the handle... These things are beautiful. I think he needs a web site, but then it would be work again.. I don't know what he calls it now.

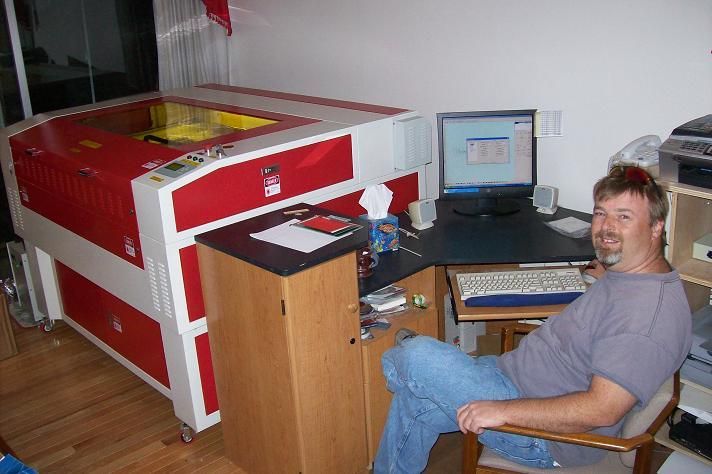

Moving the laser machine into Mike's house was one of the toughest I have done. The machine had to come apart so that it could fit through the 32 inch doorway. It then went into a short entrance and immediately down the stairs to the basement. The bottom of the stairs had barely enough room to stop, twist, and lean toward the small workshop.

Mike says I have to put his daughter's picture on here too... So here you go, Mike.

Tim Quinn runs Celtic Awards in Cleveland, Ohio. They specialize in molded awards, beveled glass, custom routed items, and lasered novelties. Tim is a great guy to do business with. He understands how business is more than money. Tim purchased a router from us and then just had to have a laser machine too. www.usasportsmedals.com

Tom owns kiosks in a few malls in North Carolina. He and his wife sell mirrored acrylic decorations in place of a car's front license tag. Tom would also love to sell you a Lamborghini-style kit car. Tom loved his machine so much that he bought another one just two months later. One machine to cut the blanks and the other do custom inlays and engravings.

Rodney Tartsah is a coach and arts teacher at a middle school in Oklahoma. He stretched his dollars far and we cut our prices deep to make sure his school got a nice laser machine. Now every teacher is asking for a laser project... I think maybe he will be a new "Big man on campus". Rodney and his school staff put us to the test on how to work with educational Purchase-Orders.

Bambi Bell enjoys going with her guy and son to the races... The deal is that Jason (14 years old) is racing quads against guys a few years older than he is.. and he is winning. Bambi is pushing to improve the quality of the awards and push into other markets of laser engraved novelties and "scratch art".

Bambi and Mark have a small (cozy) home just East of Tulsa, OK. As soon as I go to her home, I got worried if the laser machine would fit. There weren't any stairs to worry about, but the doorways and extra tight turns in the hallway had me scared. Before we took the laser machine apart, I wanted to make sure. I measured with a tape ruler.. I still wasn't convinced. I actually measured and cut out a piece of cardboard box and took it through the doors and hallways to see if it would really fit. This was proof to me that the RL-60-9060 will fit into any house. We tipped the main section of the laser machine on its end and placed it on a moving castor-dolly. I was so impressed that I had Jason taking pictures of us scooting the machine and twisting it around the tight corners of the hallway. Maybe Jason should also get a job as paparazzi. ... He can balance on top a jack with one foot, swing a bungee cord, and takes pictures too.. Maybe he sounds goofy, but he can ride a quad like nothing I ever saw. I am sure that he is Bambi's heart and inspiration.

John McNerny is part owner of an internet-based hobby store. They will be using the laser to cut model rocket fins, parachutes, RC airplane kits.. and anything else they can think of. John says he predicts his biggest problem will be to keep the employees' personal projects to a minimum.

Don Roberts owns American Plastics, a laser-cut plastics store in Columbus, Ohio. Don had purchased his first Rabbit laser machine a few years earlier from another supplier. That laser machine was accidentally caught on fire. Because Rabbit Laser USA keeps laser machines in stock in Ohio, we were able to get him back working and into business within a few days. On some evenings and weekends, Don's workshop turns into a garage for working on his car hobby. Don is a big guy... VERY nice guy.

John and Sandra run a design and prototyping service in New York City. They use the laser machine for making models of buildings and other advertisements. Moving their machine into their office is featured in our tutorial for how we moved a BIG machine through a narrow passageway.

Rudy Ambra owns a printing advertising company in the southern tip of Florida. He is a great business man. studies his investments well. Rudy uses the laser machine to make novelties for his customers. I am sure that he will be making advertisement brochures for me ... someday soon.

Jim Cota and his wife are the heart and soul of JC Signs of Minnesota. They make nearly any sign that can be made.. And he makes life fun. He was so excited after he got his laser machine that he started engraving and cutting anything he could find. ..Wood, vinyl, leather, glass. He got so good that he cut his name into his old leather jacket... Key word is "cut" ...Oops! It was a grand learning experience. There is lots of fun with this guy and his loving wife. Really... Jim has gotten VERY, VERY good at using his laser machine. www.jc-signs.com

Don't miss out on our ever-changing inventory of used CO2 and fiber laser machines. Call 513-217-5707 now for more information about our available machines, and let us help you find the perfect solution for your laser cutting and engraving needs.