- Sand the surface to reduce buildup and char.

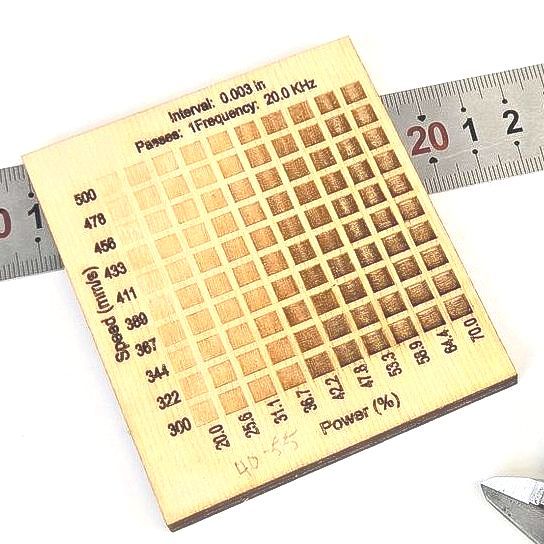

- Run a LightBurn Material Test on a small area to dial in your settings.

- Use good ventilation—reclaimed materials often release more smoke than fresh, untreated wood.

Laser Engraving Reclaimed & Composite Woods: Key Tips & Risks

Not all wood is laser-friendly—especially when it’s been salvaged from a shipping pallet or pulled from a bargain bin. If you’re using a CO₂ laser for engraving or cutting reclaimed or engineered wood, it’s critical to know what you’re working with. Let’s break down what to expect, what to avoid, and how to get better results using reclaimed wood, MDF, plywood, and more.

Reclaimed Wood:

Rustic Texture, Hidden Dangers

There’s a lot to love about reclaimed wood. It’s affordable (or free), naturally weathered, and perfect for rustic signage and upcycled projects. But hidden inside that beauty can be real problems for your laser machine.

What to watch for:

- Metal fragments – Old nails, screws, or staples can ruin a laser head if not removed. A magnetic stud finder or strong rare-earth magnet can help detect embedded metal before you cut.

- Unknown treatments – Many reclaimed boards have been painted, stained, or pressure treated. These coatings can release harmful fumes or even contain lead.

- Surface inconsistencies – Warping, cracks, or leftover adhesives can cause uneven engraving or unexpected flare-ups.

Laser engraving tips for reclaimed wood:

🔍

Heads Up: If you’re not 100% sure where that wood came from, assume it’s treated. It’s not worth risking your health or your machine.

Composite Woods:

Predictable Performance with a Catch

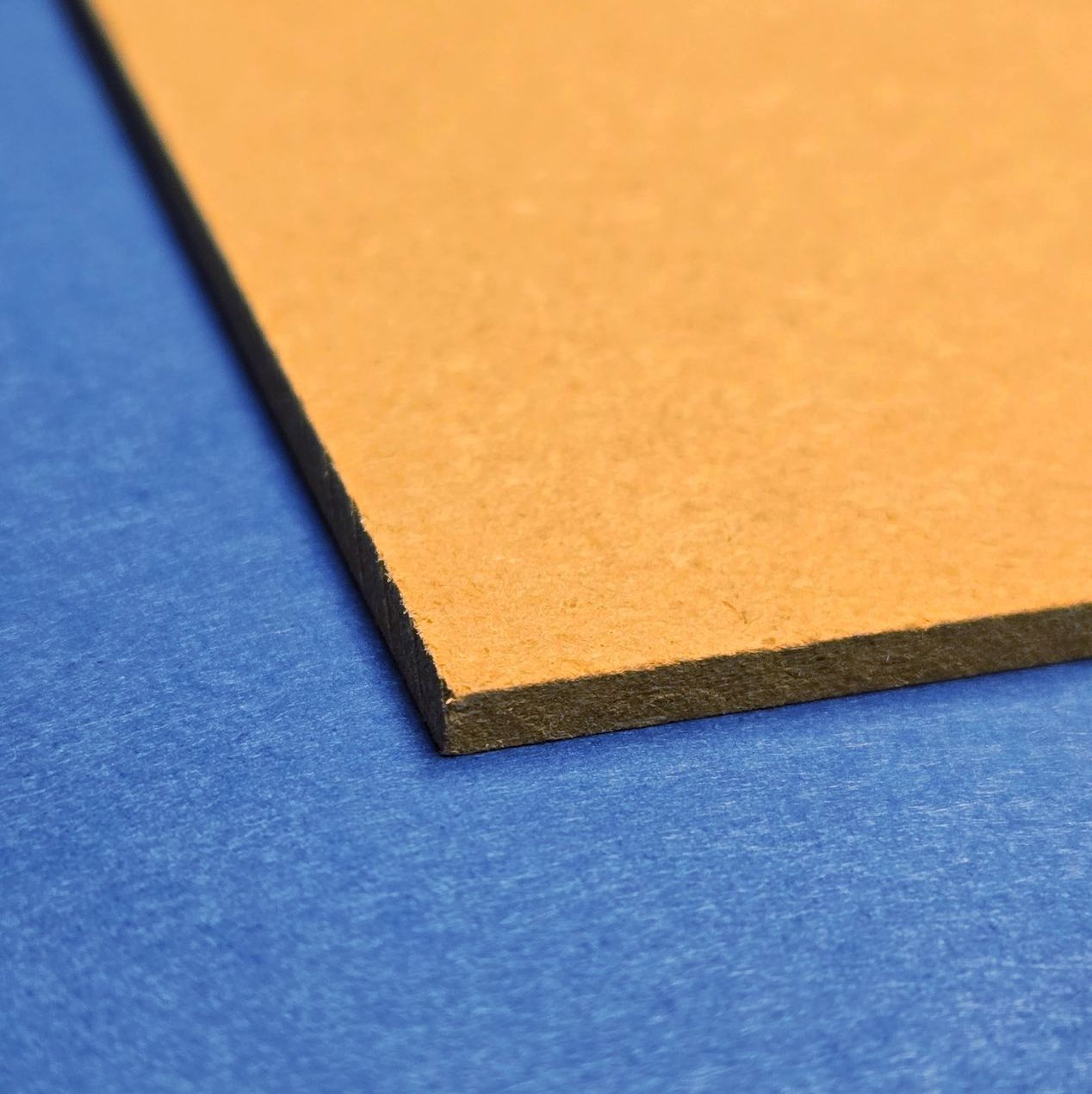

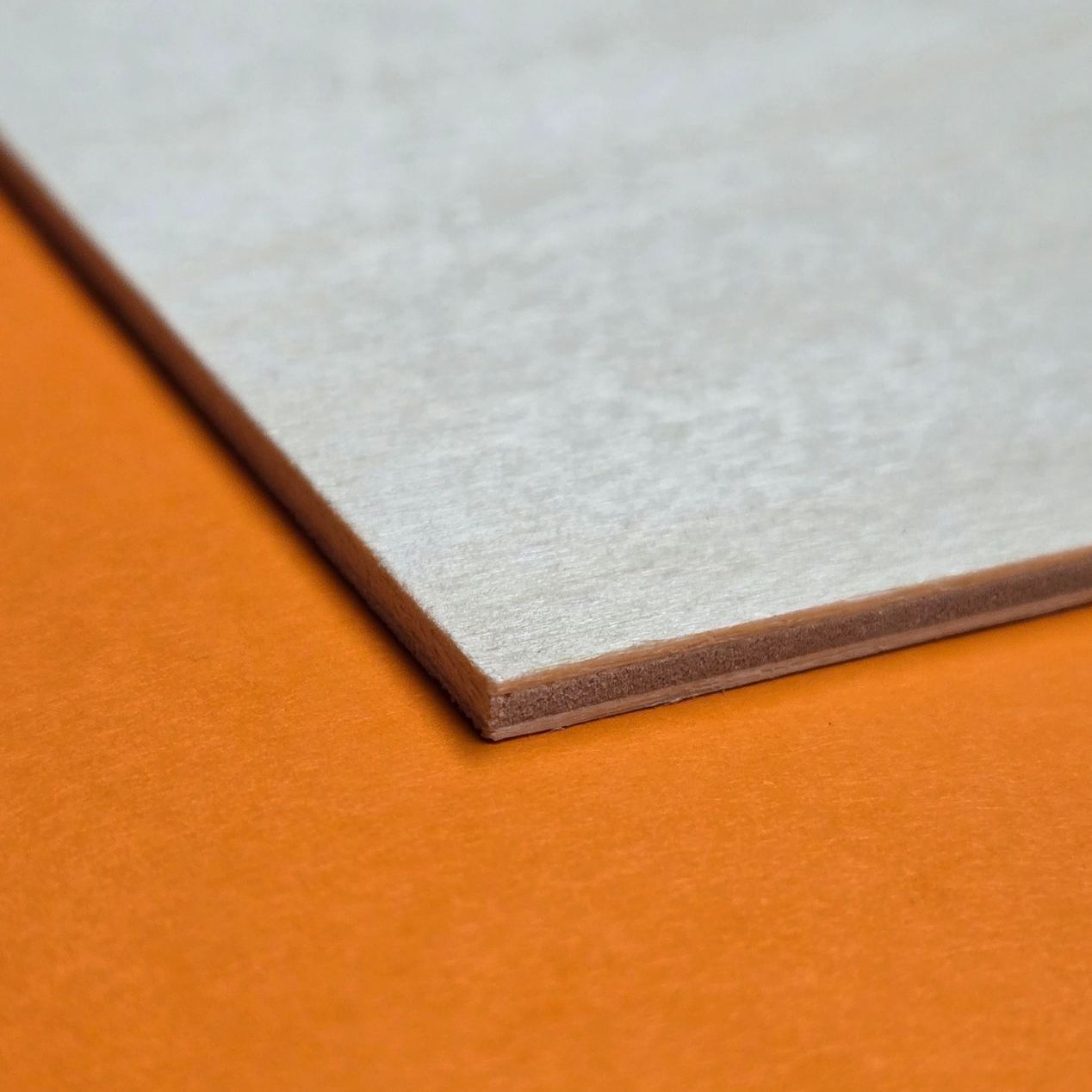

Composite materials like MDF, plywood, and HDF are popular choices for laser cutting. They’re cheap, flat, and easy to work with—but they’re not without their challenges.

MDF / HDF

Plywood

Particle Board

💡 Pro Tip: If a sheet of “wood” has no clear labeling or feels unusually heavy, it’s likely a mix of resin and filler—best avoided for laser work.

When to Use (or Avoid) Each Type

Reclaimed Wood

✅ Rustic signs, farmhouse-style art, budget-friendly experiments

🚫 Projects involving food, skin contact, or highly detailed engraving

MDF / HDF

✅ Prototypes, stacked lettering, inexpensive practice material

🚫 Projects in confined spaces with poor ventilation

Plywood

✅ Boxes, product-ready signage, wall art

🚫 Projects requiring flawless edges or fine cuts with zero cleanup

Final Checks Before You Laser

Before hitting “start,” ask yourself:

- 🔍 Did you sweep the material with a magnet or magnetic stud finder?

- 🎨 Is the surface clean and free of paint, oils, or treatment?

- ✂️ Have you sanded rough spots to prevent flare-ups?

- ⚙️ Did you run a Material Test in LightBurn?

- 🌬️ Are you using proper exhaust or filtration?

Cut corners with prep, and you risk poor results—or worse, damage to your laser.

Conclusion

Reclaimed and composite woods can absolutely work for laser engraving and cutting—you just need to do your homework. From checking for metal to running a quick LightBurn test, a few simple steps go a long way in keeping your projects clean, your air safe, and your machine in top condition. 🐰

Have a favorite reclaimed or MDF project you’re proud of? Tag us @RabbitLaserUSA—we’d love to see what you're making.