- PVC/vinyl – Produces toxic chlorine gas that’s unsafe for you and your machine.

- Coated or treated fabrics – Finishes can burn unpredictably, leaving messy edges and hazardous fumes.

- Fire-retardant fabrics – Often melt, char, or discolor in ways that ruin the cut.

Laser-Cutting Fabric: What Works, What Doesn’t, and Why

Fabric projects are popping up everywhere in the maker world — from cosplay costumes to custom upholstery to one-of-a-kind fashion pieces. With a CO₂ laser, you can achieve clean, repeatable designs that scissors or rotary blades can’t match. But not every fabric reacts the same way under a laser beam. Some cut beautifully, others leave a mess, and a few should be avoided altogether.

This guide walks you through which fabrics are laser-friendly, which ones to steer clear of, and a few pro tips to help you get the best results.

Why Use a Laser for Fabric?

- Clean edges without fraying – No need for seam sealing or trimming stray threads.

- Complex, repeatable designs – Perfect for detailed patterns, cosplay armor cutouts, embroidery backings, and custom patches.

- Scalable production – From prototypes to small-batch runs, lasers save time compared to manual cutting.

Fabrics That Work Well with CO2 Lasers

Not all fabrics are created equal, but here are a few that consistently perform well:

- Natural fibers – Cotton, silk, and wool cut cleanly and engrave with nice contrast.

- Synthetic fibers – Polyester, felt, and fleece are popular because they cut quickly and resist fraying. Just watch for slight melting at the edges.

- Blends – Poly/cotton blends and canvas balance the strengths of both fiber types and are common in upholstery and promotional goods.

These options open up projects like apparel patches, theater costumes, signage backdrops, and branded merchandise.

Fabrics to Avoid (and Why)

Some textiles simply don’t mix with lasers:

Tips for Clean Laser Cuts on Fabric

Engraving on Fabric: Creative Applications

Cutting isn’t the only option — engraving can unlock unique textures and patterns:

- Leather patch engraving for hats or bags.

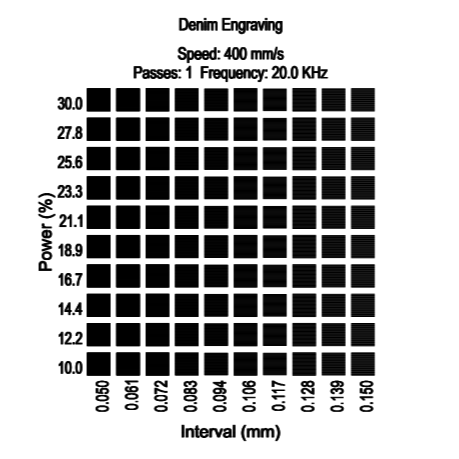

- Custom artwork on denim jackets and fleece blankets.

- Quilting templates and embroidery guides.

- Upholstery branding for furniture shops.

Machine Setup & Accessories That Help

- Adjustable air assist – Fine-tunes airflow to reduce scorching.

- Rotary attachment – Allows rolling fabrics or cylindrical textile items.

- Hold-down solutions – Weights, pins, or magnetic clamps prevent shifting.

These small add-ons can make the difference between an average cut and a production-ready finish.

Common Mistakes to Avoid

Conclusion

Laser-cutting fabric opens new possibilities for makers, schools, and small businesses. From intricate cosplay details to personalized upholstery branding, a CO2 laser offers precision and repeatability that traditional tools can’t match.

Just remember: not all fabrics are safe or suitable, and the right setup makes all the difference.

At Rabbit Laser USA, we calibrate every machine for versatility across materials — and we back it up with lifetime support to help you explore fabric, wood, acrylic, and beyond with confidence.