Class 1 Laser Safety: What It Means for Your Shop

A high school teacher recently called us, worried about letting students near a laser machine. “Can I really trust them around it?” Fair question. Whether you run a classroom, makerspace, or business, safety is everything.

Here’s what “Class 1” really means—and how Rabbit Laser USA keeps your team safe without slowing you down.

What “Class 1” Really Means

A Class 1 laser product is considered safe during normal operation because the beam is fully enclosed. Standards like IEC 60825-1 (recognized by the FDA/CDRH in the U.S.) define this rating. Many enclosed systems use a higher-class source internally (often Class 4), but the cabinet and interlocks prevent exposure—so the overall machine is Class 1 in normal use.

Translation: when the enclosure is closed and interlocks are intact, there’s no hazardous eye or skin exposure.

Never operate with doors/openings defeated or interlocks bypassed. Doing so voids Class 1 conditions.

Why Safety Ratings Matter

(Schools, Makers, Businesses)

A Class 1 rating:

- Reduces liability and smooths insurance conversations

- Reassures parents, staff, and customers that you take safety seriously

- Lets you run day-to-day engraving/cutting with confidence

Rabbit Laser USA’s Built-In Safety Features

- Full metal enclosure (beam fully contained)

- Keyed power switch (prevents unauthorized use)

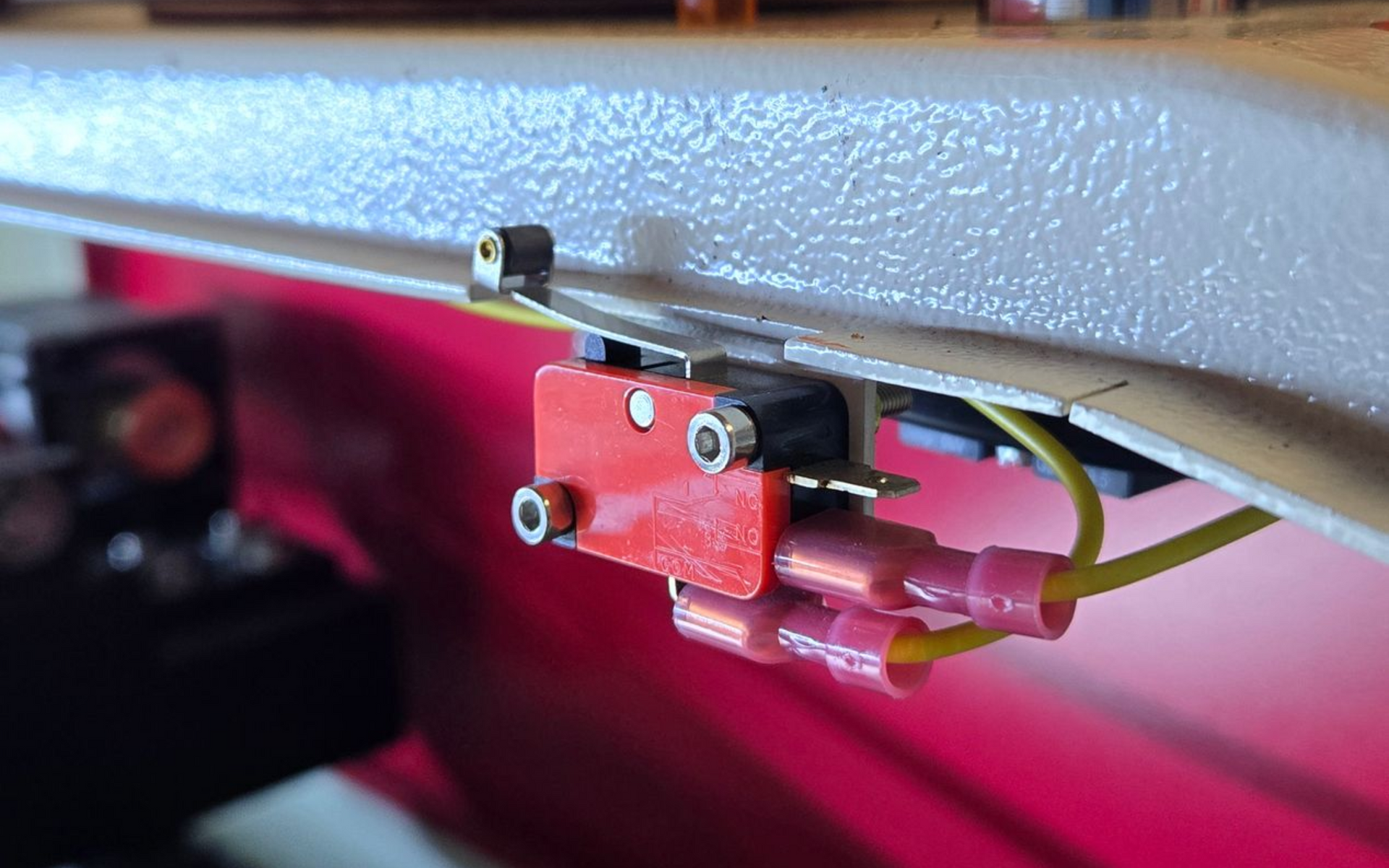

- Door interlocks (auto-pause on open)

- Emergency stop within arm’s reach

- Water-flow sensor (blocks firing if cooling fails)

These come standard, so your Rabbit arrives as a safe Class 1 laser product out of the crate.

4–6 Hour Install & Training: Safety Included

During delivery we:

- Level the machine and align optics

- Confirm exhaust airflow and electrical setup

- Teach LightBurn basics and safe workflows

- Perform a

full safety demo, including interlock tests

Lifetime Support—What It Looks Like

“They had me back up and running the same day.” — Mike H.

“They answered every question and made sure we felt confident.”

— Sarah T.

Since 2004, our U.S. team has supported schools, makers, and shops with phone, video, and on-site service.

Five 5-Minute Safety Habits

✅ Check the interlock

- Close the door, start a low-power job, open door—verify it pauses instantly.

✅ Inspect exhaust & filters

- Clear airflow = cleaner air and cooler parts. Empty catch bins; verify duct seals.

✅ Wipe optics (lightly)

- A quick lens/mirror clean keeps your beam consistent. Use approved wipes only.

✅ Verify PPE on hand

- Keep safety glasses (for maintenance tasks), gloves for handling hot parts, and a CO2 or ABC extinguisher nearby.

✅ Post visible signage

- Let visitors know a laser is operating; add a simple materials-approved list at the machine.

Ready to Cut Safely?

Want a Class 1 enclosed CO2 laser with real training and lifetime support?

Educators & Military: Ask about our always-available discounts.

Cut. Create. Conquer.