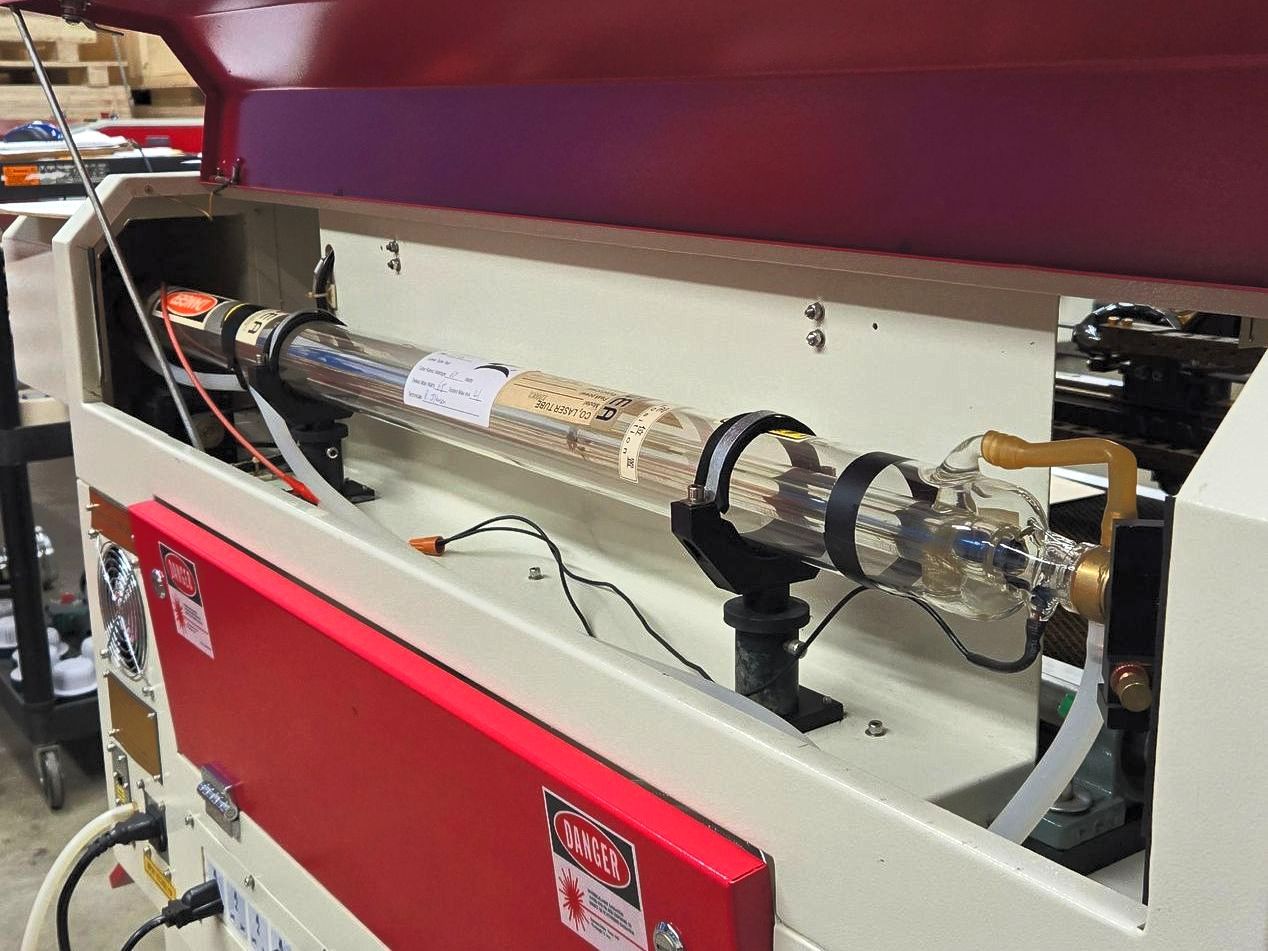

Not all tubes are the same length or diameter—even within the same watt class. A 90W tube is generally longer than a 60W, and may not fit inside your machine’s existing housing without modification.

- Measure available space in your machine's tube compartment.

- Compare tube length and diameter of your current vs. proposed upgrade.

- Check for mount compatibility—you may need adjustable or offset brackets.