Great for:

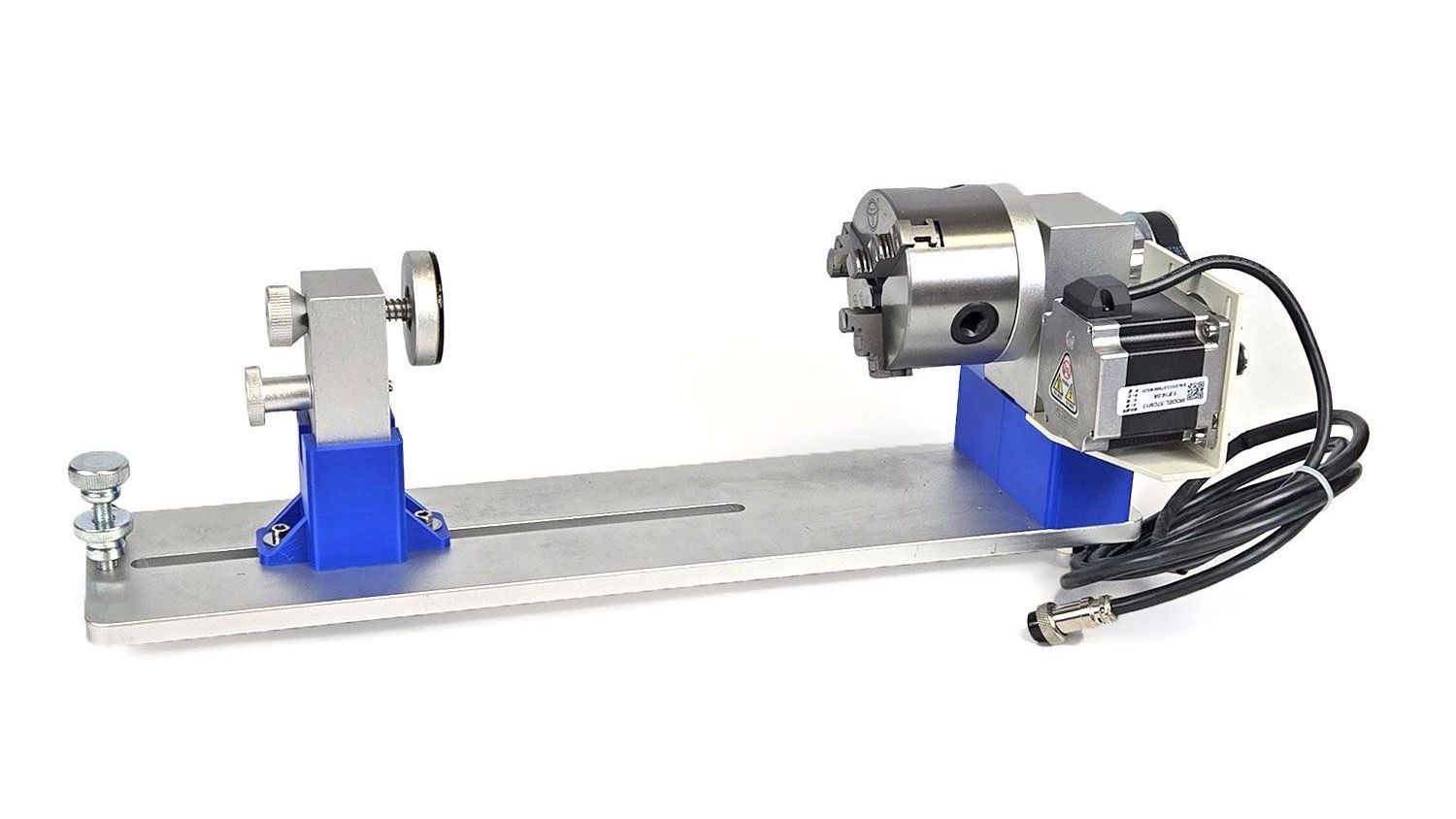

- Custom tumblers (rotary compatible)

- Small signage, ornaments, tags, and engraved gifts

- Schools, home-based businesses, and tight workspaces

- Pre-cut materials like 12" × 20" and 12" × 24" blanks

Why It Works:

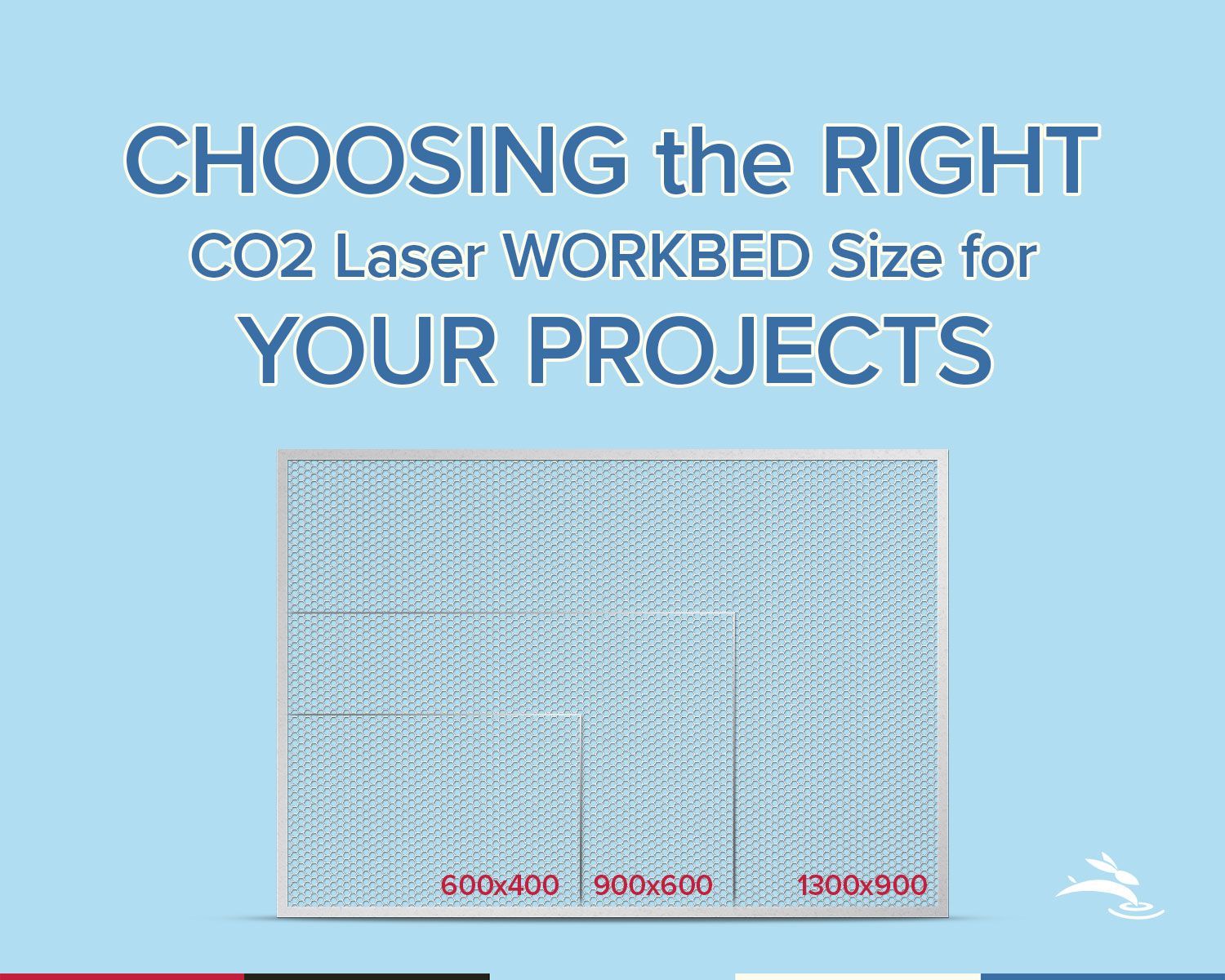

The 600×400 mm bed is our most compact option, but still features professional-grade performance. Built into a durable cabinet, this machine is ideal for shops with space limitations that still want production-grade results.