- Produces clean, polished edges when cut

- Engraves with a frosted white appearance

- More forgiving with speed and power settings

- Ideal for signs, awards, display pieces, and decorative projects

Mastering Acrylic Cutting: A Comprehensive Guide

Laser cutting acrylic can look effortless in videos—but in real life, the results depend on details. The right material, airflow, setup, and settings make the difference between clean, glossy edges and cloudy, melted cuts.

This guide breaks acrylic cutting down in a practical, no-nonsense way. Whether you’re new to laser cutting or just want more consistent results, this will help you dial things in with confidence.

Understanding Acrylic (And Why It Matters)

Before cutting anything, it’s important to know what acrylic actually is—and what it isn’t.

Acrylic is commonly confused with plexiglass or polycarbonate. While they may look similar, they behave very differently under a laser. Acrylic cuts cleanly and predictably. Polycarbonate does not. Cutting the wrong material can create excessive smoke, poor results, and even damage your machine.

Always confirm the material before cutting.

Types of Acrylic You’ll Encounter

Not all acrylic cuts or engraves the same. The two most common types you’ll work with are cast acrylic and extruded acrylic, and knowing the difference will save you time, material, and frustration.

One of the easiest ways to tell them apart is by looking at the masking and engraving result:

- Cast acrylic usually has paper masking and engraves to a frosted white finish.

- Extruded acrylic typically has plastic film masking and engraves clear rather than frosted.

Cast acrylic

Cast acrylic is the preferred choice for laser engraving and cutting.

If you care about edge quality and engraving contrast, cast acrylic is usually the better option.

Extruded acrylic

Extruded acrylic behaves differently under a laser and requires more control.

Because it melts more easily, extruded acrylic demands tighter control of speed, power, and airflow to avoid rough edges.

If you’re ever unsure which type you’re working with, run a small engraving or test cut first. The masking and engraving result will usually tell you exactly what you have.

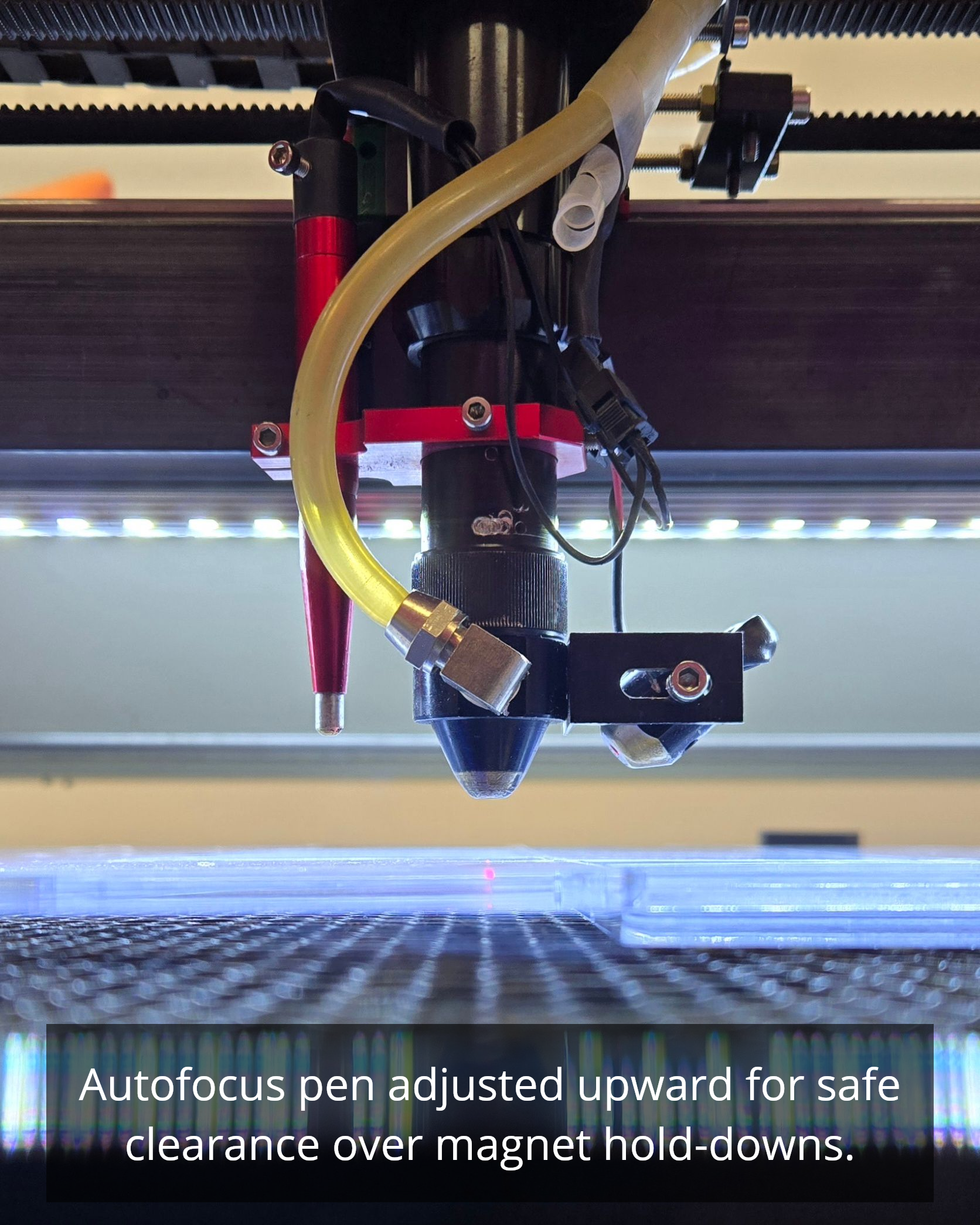

Airflow: One of the Most Overlooked Factors

Good airflow is critical when cutting acrylic. It helps remove heat, clears debris from the cut path, and improves edge quality.

A vacuum table or effective exhaust system helps pull smoke away from the material while keeping the cutting area cool. Proper airflow also reduces flare-ups and keeps cuts consistent across the entire sheet.

More airflow isn’t always better. Too much air can shift small parts or cool the cut too aggressively. The goal is steady, controlled movement of air—not a blast.

Elevate the Material to Prevent Flashback

Dialing in Speed and Power

There’s no universal speed and power setting for acrylic. Thickness, color, machine wattage, and lens choice all play a role.

A good approach is to:

- Start slower than you think you need

- Make small adjustments

- Run test cuts before committing to the final job

If edges look melted or cloudy, reduce power or slow down.

If cuts don’t go through cleanly, increase power slightly or reduce speed.

Consistency comes from testing—not guessing.

Masking and Surface Protection

Leaving the protective paper or plastic film on acrylic during cutting can help prevent smoke residue and surface marks.

Masking is especially helpful for:

- Light-colored or clear acrylic

- Pieces with engraved details

- Jobs where surface finish matters

Just remember to remove masking after cutting for best visual clarity.

Quick Checklist Before You Cut

Before hitting “Start,” run through this quick checklist:

- Confirm material is acrylic

- Mask protective film if you want cleaner surfaces

- Check airflow + vacuum table setup

- Lift material off bed to avoid flashback

- Do a small test cut

- Adjust settings based on test results

These steps take minutes and save wasted material.

Common Acrylic Cutting Questions

Why do my edges look cloudy?

This usually means too much heat. Reduce power slightly or increase cutting speed.

Should I cut acrylic in multiple passes?

Single-pass cuts are preferred when possible. Multiple passes can re-melt edges and reduce clarity.

How thick can acrylic be cut?

That depends on laser wattage, lens choice, and airflow. Testing is always the best indicator.

Final Thoughts

Acrylic is one of the most rewarding materials to laser cut—but only when the setup is right. Small adjustments in airflow, elevation, and settings can turn frustrating cuts into clean, professional results.

Take the time to test, pay attention to edge quality, and build settings that work for your machine. Once dialed in, acrylic becomes one of the most reliable materials in your shop. 🐰